How Coconut Oil is Made: The Ultimate Guide

How Coconut Oil is Made: The Ultimate Guide.

With more and more people discovering and questioning the benefits of totally natural, cold-pressed virgin coconut oil, we’ve been getting more interest from customers at Virginutty on exactly how coconut oil is made.

We’ll be the first to admit that there’s endless terminology to wade through (difference between unrefined, raw and virgin coconut oil, anyone?).

So we’ve created this guide to the industrial coconut oil production process used in coconut-producing countries, so you can find out exactly how coconut oil is made and be able to choose the right coconut oil for your needs.

We’re all about making informed decisions.

As a champion of conscious consumerism, we believe it’s important that you know exactly how the natural products you use daily get to you.

So in this article we’re breaking down everything you need to know about how coconut oil is made not only from a production point of view, but also from an environmental and socioeconomic standpoint across the entire supply chain - so you can make a fully informed decision the next time you buy virgin coconut oil.

OK, so how exactly is coconut oil made?

While there are more oil extraction methods than we can count, they all fall under the umbrella of two main methods: heated or unheated (aka ‘cold pressed’) methods.

Both of these methods extract the oil from the white flesh (or ‘meat’) of the coconut, which is where all coconut oil comes from.

How is coconut oil made using hot-pressed methods?

The first group of methods apply a hot press (also known as an ‘expeller press’) to extract the oil from freshly dried pulp of coconut kernels. In the coconut agriculture industry, these dried kernels are known as ‘copra’.

There are three main hot-press methods in use today:

1. The Centrifuge Method

In this method, coconut milk is first extracted from the meat of the coconut. The coconut that remains is spun at high speeds within a centrifuge to separate the oil from the meat.

The spinning process means that a high amount of heat is generated and applied directly to the coconut. Although the taste and aroma of the coconut remain and don’t need further refining, many nutrients are removed when heat is applied during the spinning process.

2. The Heated Expeller Method

When heated expellers are used, a chemical solvent called hexane is applied to crushed, dried coconut to extract oil from the meat of the coconut.

The coconut oil extracted using this method typically needs to be further refined to create a commercially acceptable product, and if this hasn’t been done properly there’s risk of residual solvents remaining in the final coconut oil.

3. Chemical extraction

In this method, oil extracted from the coconut is refined using a chemical distillation process that uses harsh solvents like lye. Or they’re extracted from rancid oil by-products leftover from creating desiccated coconut flakes.

Any oils produced using this method tend to be hydrogenated or partially hydrogenated. This is by far the most unnatural extraction process with a high chance of leaving residual solvents in the oil.

The controversy around copra oil

Although heated methods have been used commonly around the world for centuries, the main concerns around heated extraction methods stem from the use of ‘copra’ itself.

Copra is made by drying fresh coconut kernels through arduous, fuel and labour-intensive processes that can be unhygienic due to the long process they undergo while drying in humid tropical conditions, and being subject to bulk shipping over long distances.

This can lead to the growth of moulds on the copra, potentially leading to carcinogenic contamination within the kernels.

It goes without saying that that the oil from this kind of extraction can be of a low quality, meaning that refining, bleaching and deodorising (RBD) is needed to create coconut oil which is fit for sale.

The refining process uses hydrochloric acid, solvents and steam to strip out the contamination. At best, the process removes the natural antioxidants that give pure coconut oil its unique flavour and aroma. At worst, some residual solvents and chemicals remain in the oil.

After all the processing, what can be left is a product that looks and smells like coconut oil through refinement and modification, but has very little of the benefits and is potentially dangerous if contaminated with solvents and chemicals.

How is coconut oil made using cold-pressed methods?

The second group of cold-pressed methods produce much safer and more beneficial coconut oil. They involve the use of a ‘cold press’ which extracts oil from the meat of a fresh, mature coconut. Mature coconuts are used because of the higher levels of oil content found as the coconut matures.

Compared to heated methods, numerous studies show that cold-pressed raw, virgin coconut oil preserves the natural scent, taste, bio-activity, antioxidants and vitamin E within the coconut. This also explains why cold-pressed coconut oil is often more expensive to buy.

At Virginutty we only use cold-pressed methods to extract our 100% natural, unrefined coconut oil from the Philippines.

While our coconut oil products are made using a variety of cold-pressed methods, our preferred methods either use fermentation techniques or a mechanical screw-press called a cold-press expeller to extract oil from fresh coconut meat.

And although the first few steps for extraction are similar for both of these methods, the main differences occur when the oil is extracted from the coconut.

Getting to the coconut meat

For both methods, removing the husk and shell from the coconut is the first step in gaining access to the meat of the coconut. As both the husk and shell are extremely tough, producers like ours need to use specialised equipment to remove them from the coconut.

After the husk and shell is removed, a thin layer of brownish film that lies between the coconut kernel and the shell called the ‘testa’ is also removed so nothing but the white coconut meat remains.

Preparing the coconut meat

In expeller cold-press methods, once the outer layers of the coconut are removed, the coconut kernel is then ground and dried under low temperatures so that it’s easier to extract coconut oil from the flesh of the coconut. For oils to be classified as ‘raw’, temperatures during this phase never exceed 45 degrees celsius or 113 fahrenheit.

When using fermentation methods, water is added at this stage. The coconut shreds are placed into a large mesh bag, which is then placed into an expeller.

Using the expeller to extract raw, virgin coconut oil

After grinding the coconut down, a cold press expeller is used to extract oil from the coconut meat. During this phase, producers are constantly mindful of temperatures and use water to keep the extraction equipment cool.

An additional filter-press is then used to remove any impurities, resulting in the beautifully clear, raw coconut oil we love.

Fermenting coconut milk to extract coconut oil

In fermentation methods, instead of passing the shredded coconut through an expeller, the mesh bag containing shredded coconut is ‘pressed’ by the expeller instead, producing gorgeous white coconut milk. This aromatic, nutrient-dense milk is what contains the coconut oil.

After coconut milk has been expelled, the remaining coconut fibres can be used in a number of ways. In many cases, this byproduct of the coconut oil production process is used as animal feed, but it can also be ground down and used as coconut flour.

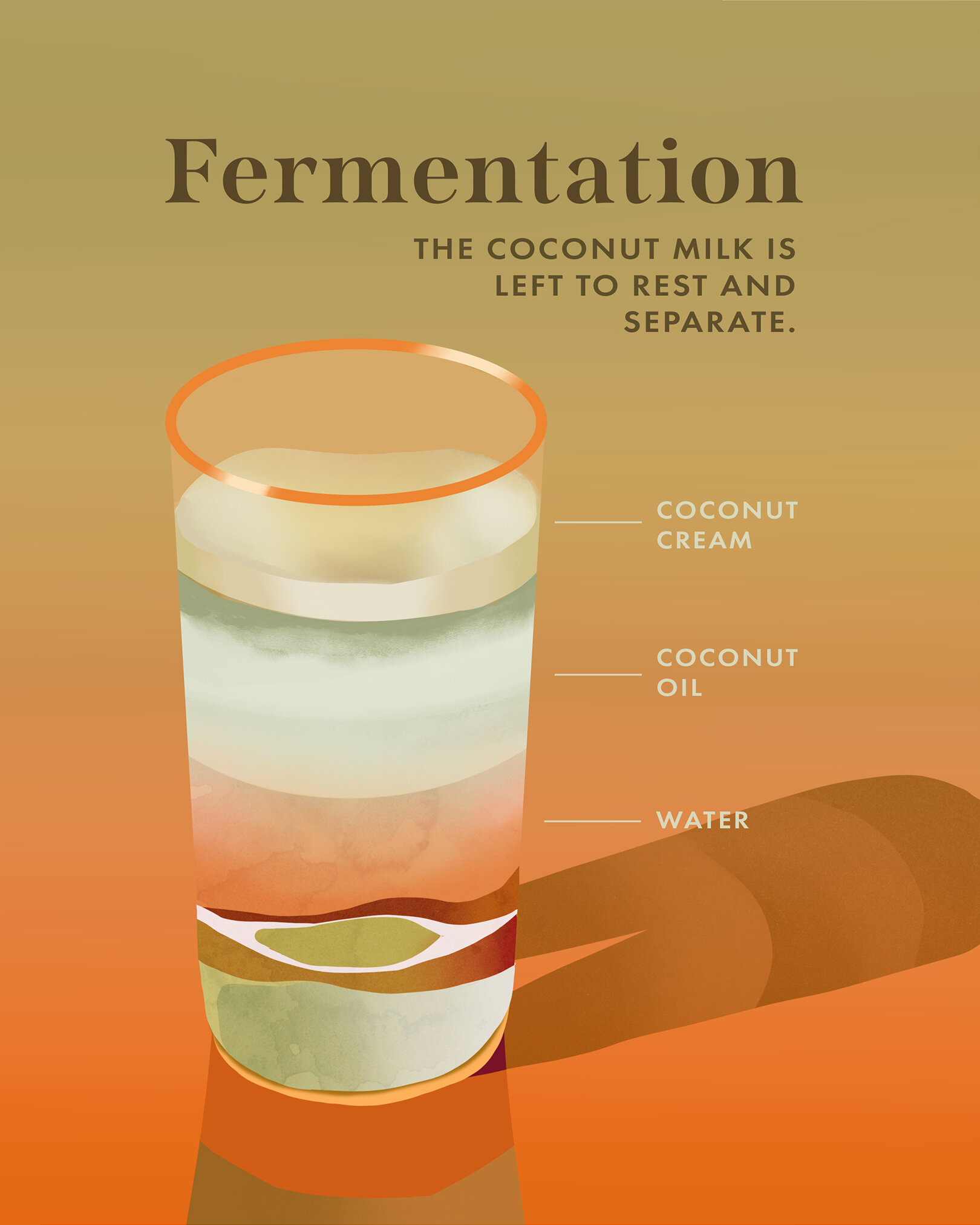

To extract oil, the fresh coconut milk is poured into large glass containers and left to rest overnight. Over a period of 24 hours, coconut cream will rise to the top, leaving water at the bottom and coconut oil in the middle.

The middle layer of oil passes through a filter press to remove impurities, leaving a slightly cloudy looking oil. This oil will then be left to rest again for about 3 days, and once again further clarified oil will rise to the top.

Any water present will evaporate through an opening in the container, leaving clear, pure and raw coconut oil behind.

How sustainable is the coconut oil production process?

From a staple food ingredient sustaining generations of families since time immemorial, to an integral part of a woman’s daily beauty ritual in cultures spanning from Indonesia to India, the life-sustaining qualities and variety of uses of the coconut are nearly unmatched by any other tropical fruit.

So it’s no surprise then that oils derived from the coconut have seen a huge increase in demand in the West; especially when it comes to virgin, raw and cold-processed oils.

The multitude of health and beauty benefits means supermarkets and beauty stores are now stocked with hundreds of varieties of coconut-derived oils, making it more difficult than ever to know exactly how the coconut oil we buy is made.

And with coconut-branded concoctions increasingly appearing in stores that have little association with pure coconut products, it’s more important than ever in today’s conscious, sustainability-focused consumer environment that you know exactly how coconut oil is made and what to look out for when buying coconut-oil products.

As a creator of sustainably farmed coconut oil products, we believe that conversations around how coconut oil is made aren’t complete without discussing the ethics involved in the coconut oil production process.

As a proud supplier of luxuriously natural, 100% organic, cold-pressed virgin coconut oil, we believe helping our customer to understand how coconut oil is made widely available allows us to demand greater clarity and transparency around the ethics of the coconut oil production process.

It’s an important step towards empowering the hard-working people at farm level who help make coconut oil available for us to buy and use globally, as well as consumers who want to know what the coconut oil production process entails.

How are farmers affected by the coconut oil production process?

Coconut oil comes from several countries around the world, but 70% of the world’s coconut oil comes from the Philippines and Indonesia. Most of the world’s coconuts are grown in small, independent farms in these countries.

Coconut farmers are normally smallholders and tenants living in poor, rural areas and using less than four hectares of land to cultivate their coconuts.

They often face poverty, and are operating with a lack of proper equipment and training opportunities. All of this means that the coconut oil production process can be challenging to sustain, with little or no economies of scale, meaning that farmers and producers can’t are unable to save money in production or farming costs as they supply more and more product.

Rigid supply chains dependent on middlemen can also mean that farmers end up with few options to improve their livelihood.

Meeting demand for coconut oil

Demand for virgin coconut oil and other coconut-based products is increasing around the world. As a result, farmers are being increasingly driven to protect their livelihoods by planting more coconut trees to maintain a constant stream of product and income.

But with the average coconut tree bearing 40-70 fruits in its lifetime, farmers can feel under pressure to meet demand for coconuts by cultivating more coconuts in the same amount of land they have access to.

Planting more trees has two main environmental consequences. Firstly, native plants and biodiversity are slowly stripped away from the local environment so that farmers can meet the demand for coconuts. Secondly, farmers end up having to use chemical fertilisers to make up for the reduced productivity of over-farmed land.

For consumers, it means the coconut oil products we love are more likely to be subject to the use of chemicals. This not only affects the quality of the coconut oil in the products we use, but also affects the quality of soil, air and water within the farming environment.

Support sustainable coconut agriculture and manufacturing

So we’ve mentioned some of the methods within the two main ways to produce virgin coconut oil on an industrial scale; by using heated and non-heated methods.

While cold pressed methods are better for farmers and the environment, rising demand for coconut oil around the world is increasingly putting pressure on farmers to create coconut products quickly so they can sustain their livelihood.

At Virginutty we’re demanding greater transparency from companies that use coconut oil in their products so that farmers are encouraged to use sustainable coconut agriculture methods.

And by using only 100% natural, virgin coconut oil from ethical Philippine sources in our products, we’re supporting businesses that produce their coconut products sustainably.

If you’ve learned something from this post, follow our journey by signing up to our newsletter to learn more about how you can help us to support sustainability in the coconut farming industry.